Base metal and weld cracks in or near the girder top flange can only occur when tension stresses are larger than the extremely large static compressive forces due to the weight of the crane. The tension stresses are caused by both the lateral and gravity loads as they are resolved about the shear center of the unsymmetrical crane girder. All loads including the dead weight of the crane rotate about the shear center of the girder cross section. This is how tension forces are created in what is normally the compression zone of a girder.

SDC performed a study of overstress by running CRANE GIRDER PRO to compare stress from a girder subject to lateral loads with the same girder subject to no lateral loading. The results of the analysis are provided below. The Hot Spot Report shows a maximum overstress of 418% for the design case with lateral loading in Zone 11-Node 30. However, when the same model is run with NO Lateral Load, the overstress of 338% is still very high. The stress at Zone 11-Node 06 is 378% with lateral load with nearly no change at 375% for the NO Lateral Load case. The conclusion is that the gravity loads of the crane cause most of the girder stress when a full torsional analysis is performed depending on node location.

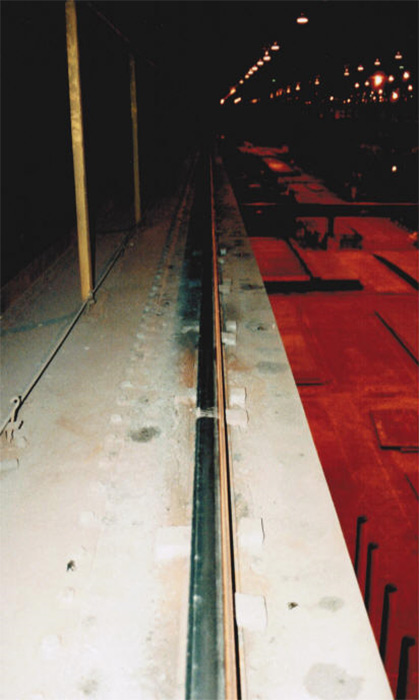

The photograph of a 112 ft. long crane girder shows a 5” bow in the bottom flange. The rotation of the top flange was so severe the crane rail could not properly bear on the girder. The rotation caused the building truss to warp as well. This girder failed due to serviceability issues. A torsional resistant girder needs to be proportioned so that is falls in the area of mixed torsion. Mixed torsion is the area between St. Venant torsion (Pure Torsion) and Warping Torsion. Crane girder design includes limiting the amount of rotation or twist. This is accomplished by proportioning the girder so that is neither St.Venant or Warping dominate to provide a girder that will not cause crane rail misalignment.

Crane operating practices can move many more tons of steel but is also a root cause of crane misalignment and damage. The misalignment leads to worn wheels and rails and larger lateral crane loads. The magnitude of the larger lateral loads is unknown and are not considered in girder design. SDC has sized crane girders for a new BOF 500T Hot Metal Crane. The design of the girder top flange is heavily influenced by the percentage of unknown lateral crane load as the ladles are moved towards the furnace. All of these factors eventually lead to structural damage to the crane runway and building components.

This is How Crane Girders Fail.